MIOTE

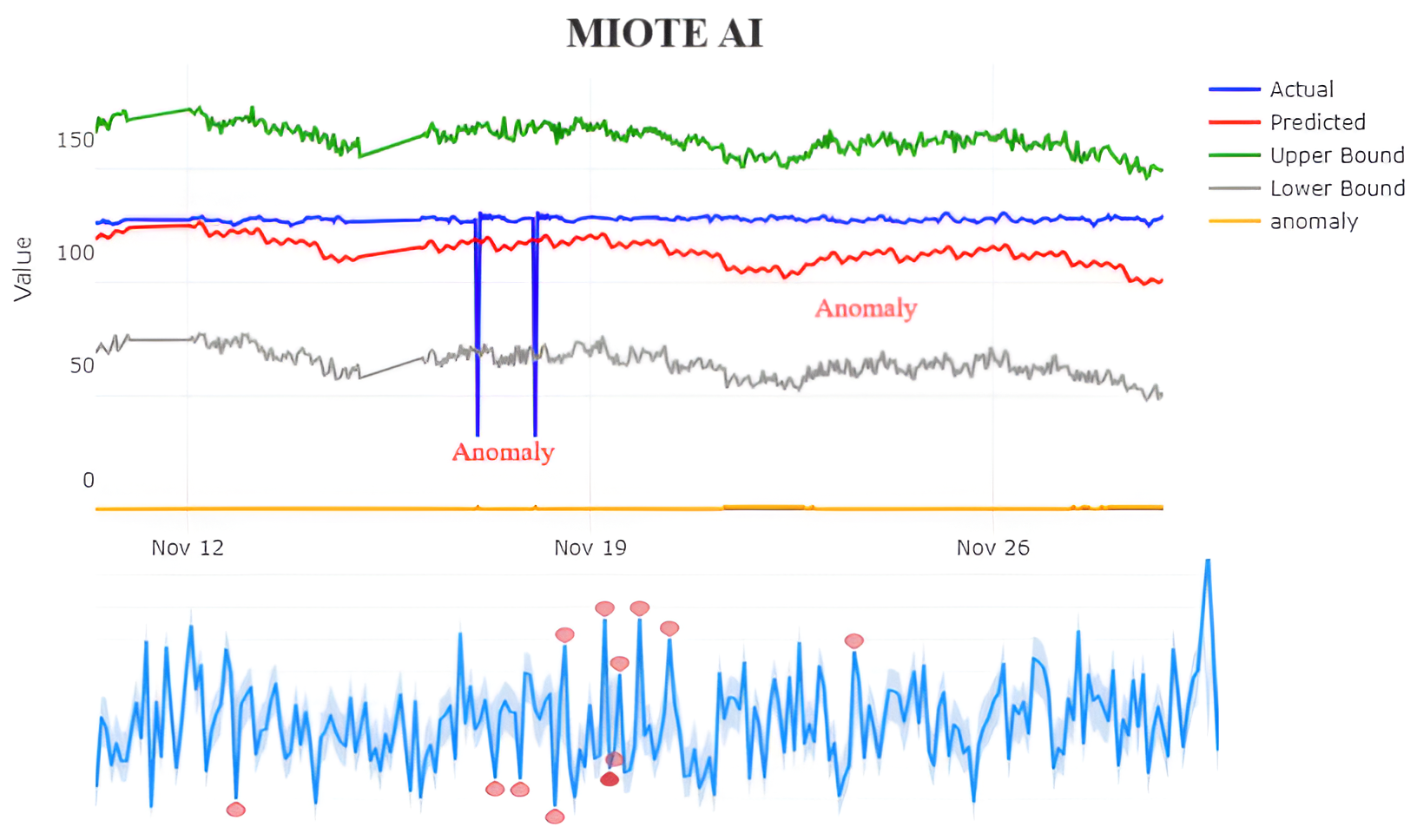

MIOTE collects continuous data from your critical electrical devices such as electric motors and transformers in your key processes. It runs time series "Anomaly detection" and "rule-based" algorithms on the gathered data, preventing unexpected downtimes and providing effective maintenance plans.

- Performs anomaly detection.

- Facilitates easy access through mobile and web applications.

- Generates effective maintenance plans.

- By conducting demand and electricity consumption trend analyses, MIOTE prevents unwanted consumptions

MIOTE provides IEC 61000-4-30 Class S measurement accuracy. By collecting data up to the 50th harmonic, it continuously gathers information for electrical devices such as a smart meter and guides the user.

- Total and fundamental active power, volt amperes reactive (VAR), volt amperes (VA), watthour, VAR hour, and VA hour

- Total and fundamental IRMS, VRMS

- Total harmonic distortion etc..

- Dip&Swell Analysis

MIOTE offers effective maintenance plans instead of traditional routine maintenance.

MIOTE can send notifications to users before unplanned downtimes and perform anomaly detection. This way, you can make preliminary detections before devices break down. You will have a precise understanding of energy expenses due to harmonic distortion for the sensitive metering of harmonic currents.

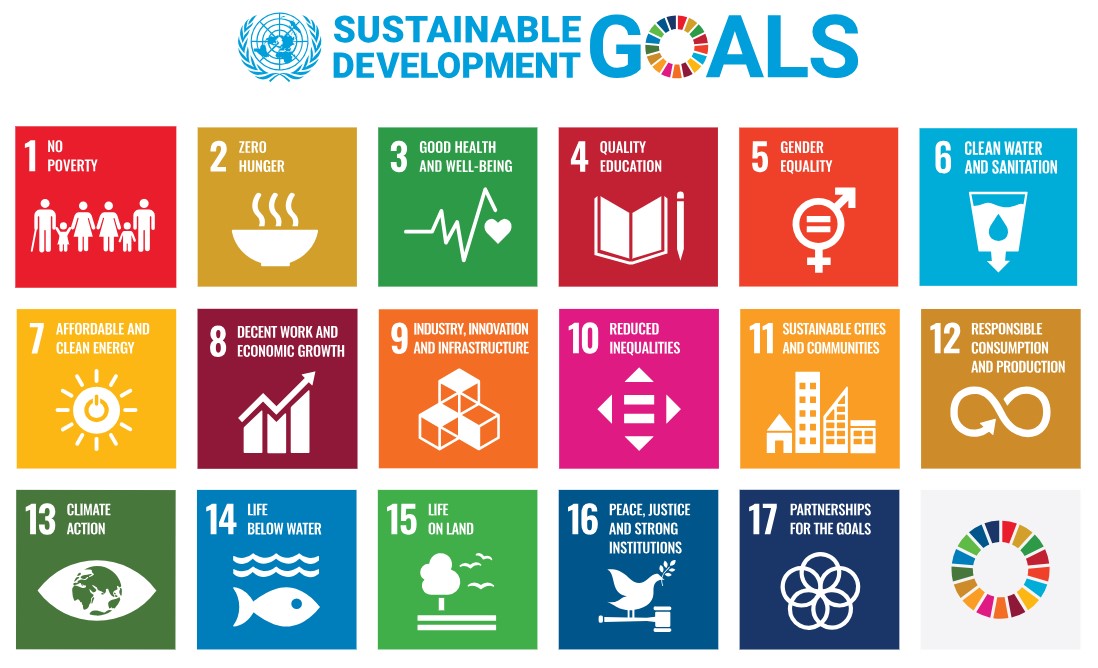

Sustainable Development Goals

MIOTE contributes to the Sustainable Development Goals (SDGs). Here are some examples of its contributions and the related SDG targets:

- Industry, Innovation, and Infrastructure (SDG 9): MIOTE enhances industrial infrastructure and offers innovative solutions for more effective and efficient production processes. This makes industrial processes more sustainable.

- Affordable and Clean Energy (SDG 7): Improved maintenance and fault prevention increase energy efficiency, helping to reduce energy consumption and carbon footprint. This promotes the use of clean and sustainable energy.

- Decent Work and Economic Growth (SDG 8): MIOTE's efficiency and fault prevention contribute to uninterrupted business operations, aiding economic growth. It also reduces operational costs for businesses, increasing economic efficiency.

- Responsible Consumption and Production (SDG 12): MIOTE contributes to sustainable consumption and production models by ensuring more efficient use of resources and reducing waste production.

- Climate Action (SDG 13): Enhancing energy efficiency and improving operational efficiency help in reducing greenhouse gas emissions, which is crucial in combating climate change.

About Us

- Founding and Development: MIOTE began its journey as an intrapreneurship project in 2022, transformed into a company in 2023, and continues to progress without slowing down.

- Experienced Team and Consultancy: Under the guidance of an experienced team and consultants, the company has developed the capability to build IoT systems from scratch and provide solutions for energy-related problems in various sectors.

- Sectoral Focus: The company aims to offer effective solutions in all sectors, with a special focus on industry and infrastructure companies.

- Research and Development Efforts: With the investments and support received, the company is continuing its R&D studies, aiming to develop sector-specific solutions.

- Solution Provision Capacity: The company is highlighted for its capacity to offer solutions to energy-based challenges across different sectors, thanks to the skills and expertise it has acquired.

- Founders : The founders of the company possess a profound knowledge and experience of 40 years in the field of electrical distribution networks. In addition to this, they have an extensive experience of 5 years in mobile application development and another 5 years in artificial intelligence technologies. This diverse expertise plays a significant role in shaping the company's approach to innovation and technology.

Infrastructure

Sample Size

It collects around 200 data points from the device.

Database

It performs fast queries for each device through separate NoSQL databases.

Dashboard

It provides instant notifications for immediate intervention through rule-based alarms and can perform AI-based current and voltage predictions and maintenance prioritization.

Maintance

It offers effective maintenance plans based on device age, maintenance frequency, rule-based alarms, and time series anomaly detection.

Call Us For Demo

Contact us for demo requests for your business.

Frequently Asked Questions

Welcome to our Frequently Asked Questions (FAQ) section, where we address common queries to ensure a seamless experience for our visitors.

-

Where is MIOTE used?

MIOTE can be employed in electric motors, 36/0.4 kV transformers used in distribution networks, and all devices powered by electricity.

-

What makes you different from energy analyzers?

Energy analyzers collect and present various data such as current, voltage, harmonics, and power, leaving the interpretation of this data to the user. In contrast to energy analyzers, MIOTE creates value from the collected data. Through our artificial intelligence algorithms applied to the data, it detects anomalies occurring in the device and informs the user. In essence, it interprets data and generates meaningful insights.

-

Can electrical data perform real fault detection?

Yes, electrical data can indeed perform real fault detection by utilizing advanced algorithms and artificial intelligence. These tools analyze patterns and anomalies in the data, enabling the system to identify and notify users of actual faults in the electrical system, ensuring prompt response and maintenance.

An Anomaly-based Technique for Fault Detection in Power System Networks

-

What sensors does MIOTE use for data collection?

MIOTE utilizes current and voltage sensors, and additional sensors such as humidity, temperature, and vibration can be easily integrated into the hardware upon user request.

-

What is Anomaly Detection?

Anomaly Detection is the process of identifying deviations from a normal or expected behavior model. This method helps identify abnormal patterns or values in a dataset, allowing the detection of potentially significant situations. Anomalies often represent errors, intrusion attempts, faults, or other undesired conditions. Anomaly Detection is commonly used to proactively identify and mitigate potential issues in a system or process.

-

Why do you only use electrical data?

Plug and Play systems in the industry are attempting to optimize processes using data such as temperature, vibration, pressure, and humidity. However, these collected data points are end results. For instance, in the case of excessive currents, the oil temperature of motors or distribution transformers does not change instantly. But the detection of abnormal conditions based on current, voltage, and harmonic data at that moment can identify if this is an anomaly and inform the user. Let’s give an example for vibration data: a minor snag or strain in the gear group to which a motor is connected can immediately disrupt the motor’s current, voltage, and harmonic data. MIOTE immediately compares such instantaneous changes with previous values and writes to the database in case of any deviation. This way, you learn how your electrical device behaves at a certain hour and second of a particular day of the week.